CNC Machines

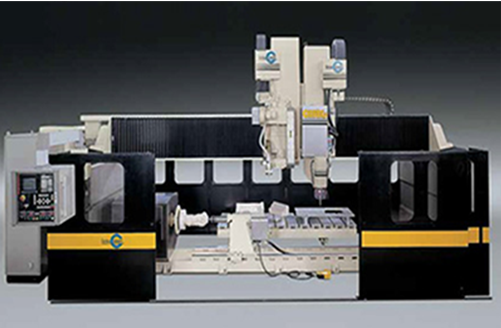

MILL4X results from 25 years manufacturing experience, which combines the best technologies with a simplicity in setting up work for forming, routing, engraving, milling, sculpting, sawing, polishing and lathe work on marble, granite, all types of stone and glass. MILL4X is a high output machine both for on-line production and for single, one-off pieces.

The axes are driven at high speed by brushless motors combined with ball bearing screws, while lasting quality and precision are assured by linear guides with ball runners, moving parts protected by PVC bellows and a centralised oil lubricating system.

The mobile bridge technology makes MILL4X a modular machine since the supplementary application of the lathe system or the extending of the work area can be done in any moment, depending on the customer requirements.

Lasimark

Omag is a machine using an innovative engraving device based on laser technology in order to get high resolution engravings.

LasiMark is an innovative tool based on laser technology.

An infrared laser beam is focused onto the surface to be engraved, locally the optical power density is sufficient to break the stone structure. The head is mounted into the numerically controlled machine tool like a normal mechanical tool.

LasiMark electronics combined with the software driver synchronises the laser pulses and the power controller to the movement of the machine tool axes plotting the desired images.

Lathe94TE

Omag is a machine using an innovative engraving device based on laser technology in order to get high resolution engravings.

LasiMark is an innovative tool based on laser technology.

An infrared laser beam is focused onto the surface to be engraved, locally the optical power density is sufficient to break the stone structure. The head is mounted into the numerically controlled machine tool like a normal mechanical tool.

LasiMark electronics combined with the software driver synchronises the laser pulses and the power controller to the movement of the machine tool axes plotting the desired images.

Blade5

Efficient and highly reliable CNC milling machine; it is projected for operations with marble, stone and granite sawblades.

The technology, precision and the reliability of a numerical control working centre make this type of machine, which has been built to work with a blade on marble, stone or granite, uniquely efficient and highly reliable.

The high speed of the movement of the axis is guaranteed by a brushless motorization combined with ball bearing screws. The sliding movement on linear guides rails and ball bearing blocks the protection of the moving parts with PVC bellows and a centralised oil lubricating system guarantee quality and durability.

The machine can take a diamond blade up to a maximum 1600 mm diameter, which can be tilted up to 140 and rotated up to 380.

The working table is fixed because the blade positions itself automatically according to the profiles and the cuts which are to be executed. The numerical controls that Omag uses come from the main worlwide companies, the software development (CAD/CAM) and the machines functions are made directly by the OMAG staff, which also assures a training and assistance service before and after the sale.

Tower7

The available size range makes it possible for customers to make the best possible choice for their specific machining needs, thus ensuring a perfectly targeted purchase Nonetheless, the precision engineering also allows threedimensional machining, low reliefs, inlays, kitchen tops,arches, capitals, sculptural columns.

For any potential need TOWER,thanks to a 54 HP electrospindle,also designed by OMAG, is able to use remarkable diameter ( 1.450) disks, highly suitable for any milling, roughing and shaping need.

Area5

AREA5 is a high-performance 5-axis CNC milling and shaping machine, designed for both manual and automatic operation, offering maximum flexibility, precision, and productivity for advanced stone processing applications.

Engineered for complex 3D machining, AREA5 enables milling, shaping, profiling, engraving, sculpting, drilling, and contouring of marble, granite, natural stone, engineered stone, quartz, and solid surfaces. The 5-axis technology allows continuous machining on multiple faces in a single setup, significantly reducing production time while delivering exceptional accuracy and surface finish.

The machine is equipped with high-speed brushless servo motors, precision ball screw drives, and linear guideways with ball runners, ensuring smooth movement, high rigidity, and long-term dimensional stability. Its robust structure minimizes vibration, enabling consistent performance even during heavy-duty milling operations.

AREA5 supports both manual control for custom and artistic stone work and fully automatic CNC programs for serial production, making it ideal for monuments, architectural elements, columns, sculptures, countertops, vanity tops, and decorative stone components.

Designed with operator convenience in mind, the machine features an intuitive CNC control system, fast setup, and easy program management. Optional automation, tool changers, and customization options allow AREA5 to be configured according to specific production requirements, ensuring high efficiency, reduced material waste, and superior output quality.